JOYE Machinery is a professional liquid filling machine manufacturer offering fully automatic solutions for bottles, jars, and pouches. Our liquid filler machines are engineered for high precision, hygiene, and efficiency—ideal for applications in food, cosmetics, chemicals, and more. Whether you’re filling oil, juice, sauce, or sanitizer, our automatic filling equipment ensures smooth operation and long-term reliability.

Our options include liquid filling machine,suace filling machine,servo motor filling machine,rotor pump filling machine,hotpoy base filling machine,pickle filling machine, etc. Plus, we can produce standard profiles and offer custom options too.

Our Filling Machine is designed for filling liquid,paste,oil,liquid detergent,viscous and granular sauces (hot and numbing sauce, sesame sauce, beef sauce, sticky chili bean sauce, fresh spicy sauce, spicy sauce, black bean sauce and Pixian Pea Sauce),pickle,etc.

Our feeding filling machine Customized the machine According to Your product Requirement.

Filling machines are essential equipment for packaging liquids, pastes, powders, and granular products. Whether you are in the food, cosmetic, pharmaceutical, or chemical industry, knowing how to operate a filling machine efficiently ensures accurate production, minimizes waste, and maintains product quality.

In this guide, we will walk you through the step-by-step process of using a filling machine properly.

Before starting, ensure the filling machine is installed on a stable, level surface. Check that all connections, including the power supply, air compressor (if applicable), and material feeding system, are properly connected. Prepare the product you need to fill and clean, empty containers for operation.

Checklist:

Power supply and air source ready

Material loaded into the hopper or tank

Containers clean and ready for use

Adjust the machine settings based on your product’s properties:

Filling Volume: Set the amount of product to be dispensed into each container.

Filling Speed: Adjust the speed to balance production efficiency and precision.

Filling Mode: Choose between manual, semi-automatic, or fully automatic modes depending on your production needs.

For viscous or foamy liquids, you may need to adjust filling nozzles or anti-drip functions.

Run a few test cycles before mass production:

Check the filling accuracy by weighing the filled containers.

Inspect for leaks, spills, or improper filling.

Fine-tune the settings if necessary to achieve optimal results.

Tip: Use the same container type and size during the trial run for best accuracy

Checklist:

Power supply and air source ready

Material loaded into the hopper or tank

Containers clean and ready for use.

Once the settings are optimized:

Start the filling machine.

Monitor the operation continuously to ensure consistent filling.

Refill materials promptly when the tank level drops to avoid air filling or machine interruption.

Operators should stay alert to any unusual noises, jams, or misalignments during production.

After production is complete:

Clean all product contact parts, including nozzles, hoppers, and pipelines.

Follow the manufacturer’s recommended cleaning procedures, especially if switching between different products.

Perform regular maintenance, such as lubricating moving parts and checking seals or valves for wear.

Proper maintenance extends the machine’s service life and ensures hygiene and operational efficiency.

Operating a filling machine is straightforward once the setup and adjustment steps are properly followed. Regular maintenance, careful monitoring, and parameter fine-tuning are key to achieving high-quality, consistent filling results.

If you are seeking reliable filling machines for your production line, Wenzhou JOYE Machinery Co., Ltd. offers a full range of high-performance filling solutions to meet your needs.

Filling machines are essential equipment in modern food production, enabling efficient, hygienic, and accurate packaging of a wide range of products. Based on different criteria such as the type of material, filling method, automation level, and packaging format, filling machines can be categorized into several types. Below is a comprehensive overview.

Filling machines vary according to the physical properties of the material they handle:

Liquid Filling Machines

Designed for low-viscosity fluids like water, juice, wine, and soy sauce. These machines often use gravity, time-based, or flowmeter-controlled filling systems to ensure high accuracy and speed.

Paste Filling Machines

Suitable for viscous products such as sauces, honey, ketchup, toothpaste, and jam. They typically use piston-type mechanisms or pneumatic systems to effectively handle thick materials.

Powder Filling Machines

Used for powdered products such as milk powder, spices, and instant coffee. Equipped with auger screws and dust-tight designs, these machines maintain cleanliness and accuracy in powder dosing.

Granule Filling Machines

Designed for granular items like sugar, rice, beans, and candies. These machines use volume-based cups or weight-based systems for efficient and consistent filling.

The filling method is determined by the product’s characteristics and packaging needs:

Gravity Filling

Relies on the natural force of gravity to fill containers. Ideal for water, wine, and other free-flowing liquids without carbonation.

Vacuum Filling

Uses negative pressure to draw liquid into containers, minimizing oxidation and preserving aroma. Common in wine, perfume, and essential oil industries.

Pressure Filling

Uses pressurized tanks to fill containers, either via equal pressure or high pressure. Essential for carbonated beverages like soda, sparkling water, and beer.

Piston Filling

A reciprocating piston measures and dispenses precise volumes of product. Especially useful for semi-liquid or viscous products such as sauces and creams.

Weighing Filling

Fills containers based on real-time weight measurements. Highly precise and commonly used for high-value or regulated products.

Depending on production scale and labor availability, filling machines offer various automation levels:

Manual Filling Machines

Simple devices for small-scale production, sampling, or laboratory use. Operators manually control filling and container movement.

Semi-Automatic Filling Machines

The filling process is automated, but operators manually feed and remove containers. Suitable for medium-output operations.

Fully Automatic Filling Machines

Integrate multiple functions such as bottle unscrambling, filling, capping, and labeling into a complete production line. Best for high-volume manufacturing with consistent output.

Filling machines can be tailored to different packaging types:

Bottle Filling Machines: Used for PET, glass, or HDPE bottles. Common in beverages, dairy, and edible oil industries.

Pouch Filling Machines: Suitable for stand-up pouches, spouted pouches, and sachets. Widely used in sauces, drinks, and condiments.

Drum Filling Machines: Designed for large-capacity drums (5L, 20L, 200L), especially in bulk oil or industrial food additives.

Can Filling Machines: Specialized for tinplate or aluminum cans, often seen in canned food and energy drink production.

Choosing the right type of filling machine depends on several factors: the product’s physical properties, production scale, packaging type, and hygiene requirements. In the food industry, where safety, efficiency, and precision are paramount, investing in the appropriate filling technology can significantly improve production quality and cost-effectiveness.

In the field of liquid filling, different types of filling machines are designed to suit specific products and production requirements. Among the most common solutions for medium- to high-viscosity products are rotor pump filling machines and piston filling machines. This article compares these two types of equipment in terms of working principles, material compatibility, and performance characteristics to help you select the most suitable solution for your application.

1.1 Rotor Pump Filling Machine

Rotor pump filling machines use a rotary lobe pump as the dosing mechanism. Inside the pump, two or more rotating lobes create a consistent cavity that draws in and pushes out product in a smooth, continuous flow. The design is based on volumetric filling, and the pump delivers precise quantities of product to the filling nozzles. With gentle shear and low pulsation, rotor pumps are ideal for handling sensitive or viscous materials.

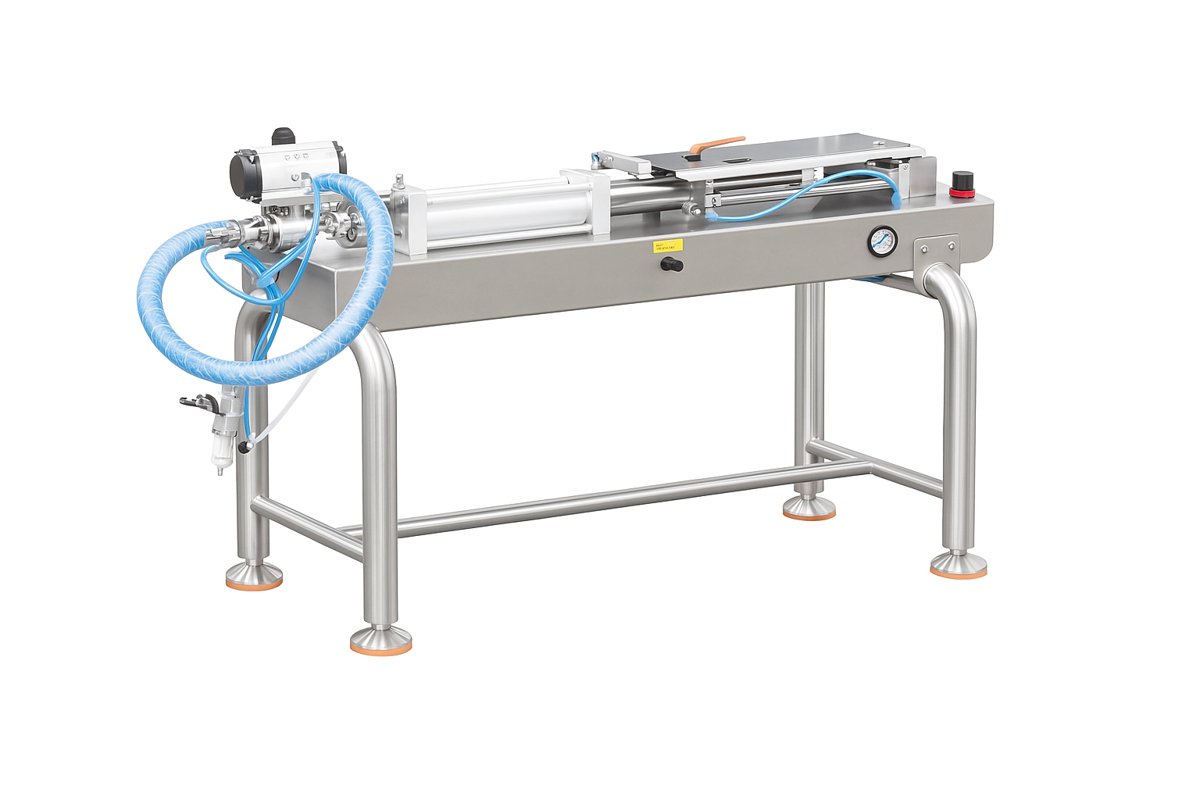

1.2 Piston Filling Machine

Piston fillers rely on the linear motion of a piston inside a cylinder to draw in and dispense a precise volume of liquid. The piston stroke determines the fill volume, making it a volumetric filling process as well. These machines are often used in semi-automatic and automatic lines with moderate output requirements and are known for their high accuracy and versatility with thicker products.

| Filling Machine Type | Suitable Materials | Typical Industries |

|---|---|---|

| Rotor Pump Filler | High-viscosity or particulate liquids (e.g., sauces, honey, creams, jam) | Food, cosmetics, pharmaceuticals |

| Piston Filler | Medium- to high-viscosity liquids (e.g., shampoo, lubricants, gels) | Personal care, chemical, food, oil |

While both machine types can handle viscous products, rotor pump fillers are better suited for particulate-laden or shear-sensitive materials, whereas piston fillers are ideal for uniform, smooth-flowing liquids and pastes.

| Performance Metric | Rotor Pump Filler | Piston Filler |

|---|---|---|

| Filling Accuracy | High (volume controlled by pump cavity) | High (volume controlled by piston stroke) |

| Filling Speed | High (continuous flow) | Medium (intermittent motion) |

| Cleaning & Maintenance | More complex (precision pump structure) | Easier (simpler mechanism) |

| Cost | Higher | Moderate |

| Sanitary Design | Typically CIP/SIP capable | Can meet hygiene standards but less automated |

In addition to rotor and piston fillers, the market offers several other technologies:

Flow Meter Filling Machines: Use electromagnetic or mass flow meters for precise dosing; ideal for high-accuracy applications in pharmaceuticals and fine chemicals.

Time Gravity Filling Machines: Fill based on time-controlled valve opening; suitable for free-flowing liquids like water or alcohol.

Vacuum/Negative Pressure Filling Machines: Create a vacuum inside bottles for uniform liquid levels; often used in perfumes and clear glass packaging.

Pressure Filling Machines: Used for carbonated drinks like beer and soda; fill under pressure to avoid foaming and CO₂ loss.

Rotor pump and piston filling machines both offer high precision and are capable of handling viscous products, but each has its advantages depending on the material characteristics, required speed, hygiene standards, and production environment. Rotor pumps are ideal for delicate or chunky materials in sanitary applications, while piston fillers are a cost-effective solution for many common semi-thick liquids.

If you are evaluating equipment for a specific product or production setup, it’s recommended to conduct sample testing and consult with experienced suppliers to develop an optimal filling solution tailored to your needs.

Please let me know if you’d like this article in PDF or Word format for printing or presentation purposes.

No. 1111, Rong da Road, Shang wang Street, Rui an City, Wen zhou City, Zhejiang Province.

If You Would Like To Visit Our Just Now,Please Contact Us and We Will Arrange a Special Bus To Pick You Up.

Copyright © 2025 Ruian Joye Machinery CO.,LTD All Right Reserved

No. 1111, Rong da Road, Shang wang Street, Rui an City, Wen zhou City, Zhejiang Province.

If You Would Like To Visit Our Just Now,Please Contact Us and We Will Arrange a Special Bus To Pick You Up.