Smart. Fast. Precise.

Our multihead weigher delivers high-speed, high-accuracy weighing for a wide range of products—from snacks and frozen foods to hardware parts. Engineered for efficiency and reliability, it integrates seamlessly with automated packaging lines, boosting productivity and consistency across your operations.

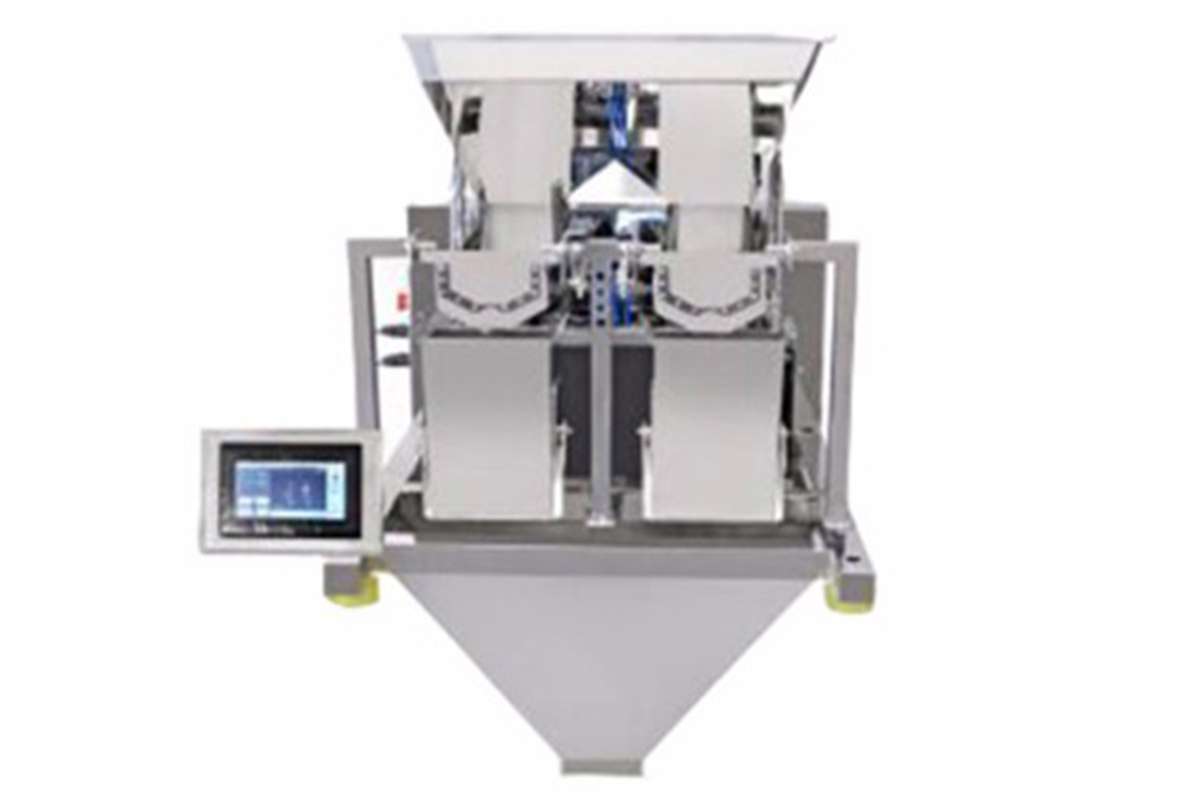

Our weigehr Machine is designed for weighing filling Block material: bean curd cake, fish, eggs, candy, red jujube, cereal, chocolate, biscuit, peanut, etc.Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer,etc.Our weigher filling machine Customized the machine According to Your product Requirement.

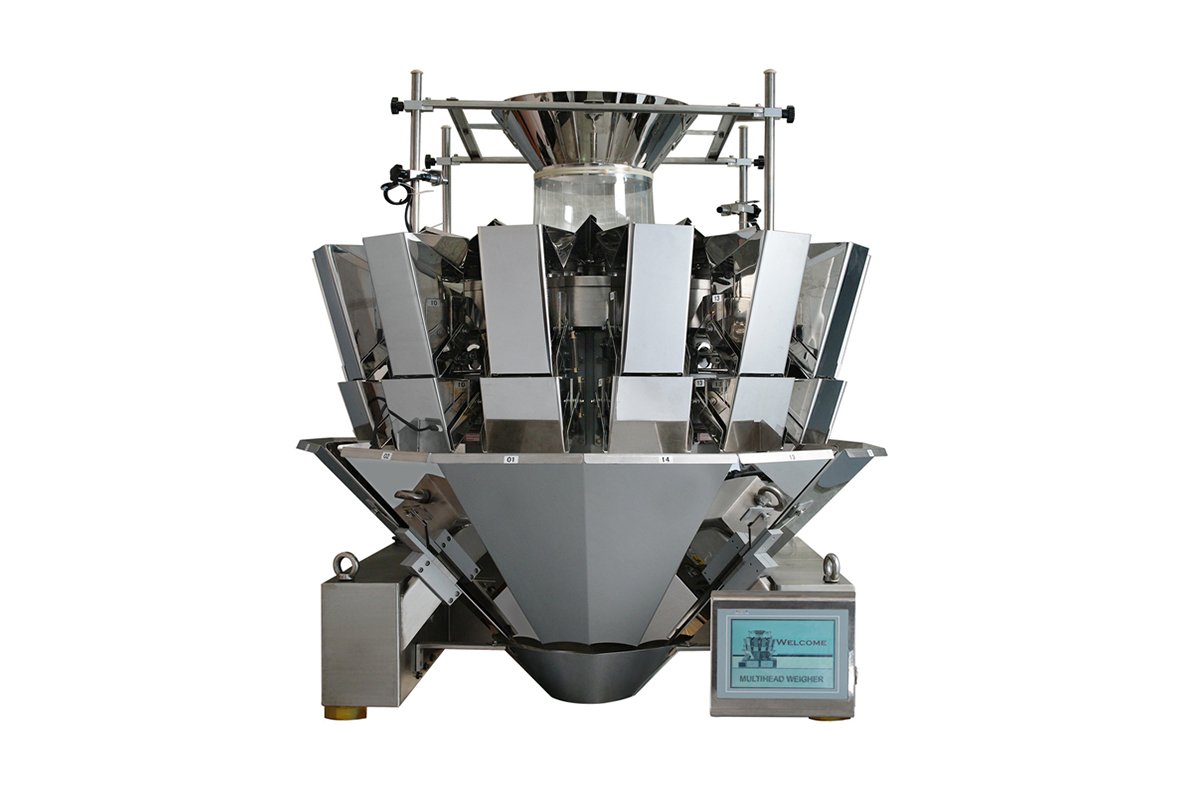

In modern packaging lines, the multihead weigher (also known as a combination weigher) has become a key piece of equipment for fast and precise weighing. Widely used in food, pharmaceutical, chemical, and hardware industries, this technology ensures high-speed, high-accuracy weighing for granular or irregular products. In this article, we’ll explore what a multihead weigher is, how it works, its benefits, and how to choose the right model.

A multihead weigher is an automatic weighing machine that uses multiple independent weighing heads to calculate the best combination of weights that matches a target value. This approach ensures minimal product giveaway and high-speed packaging.

Typically available in 10, 14, or 20-head configurations, multihead weighers are ideal for free-flowing products such as:

Candies

Nuts and dried fruits

Frozen foods (e.g., dumplings, nuggets)

Snacks (e.g., chips, popcorn)

Hardware items (e.g., screws, bolts)

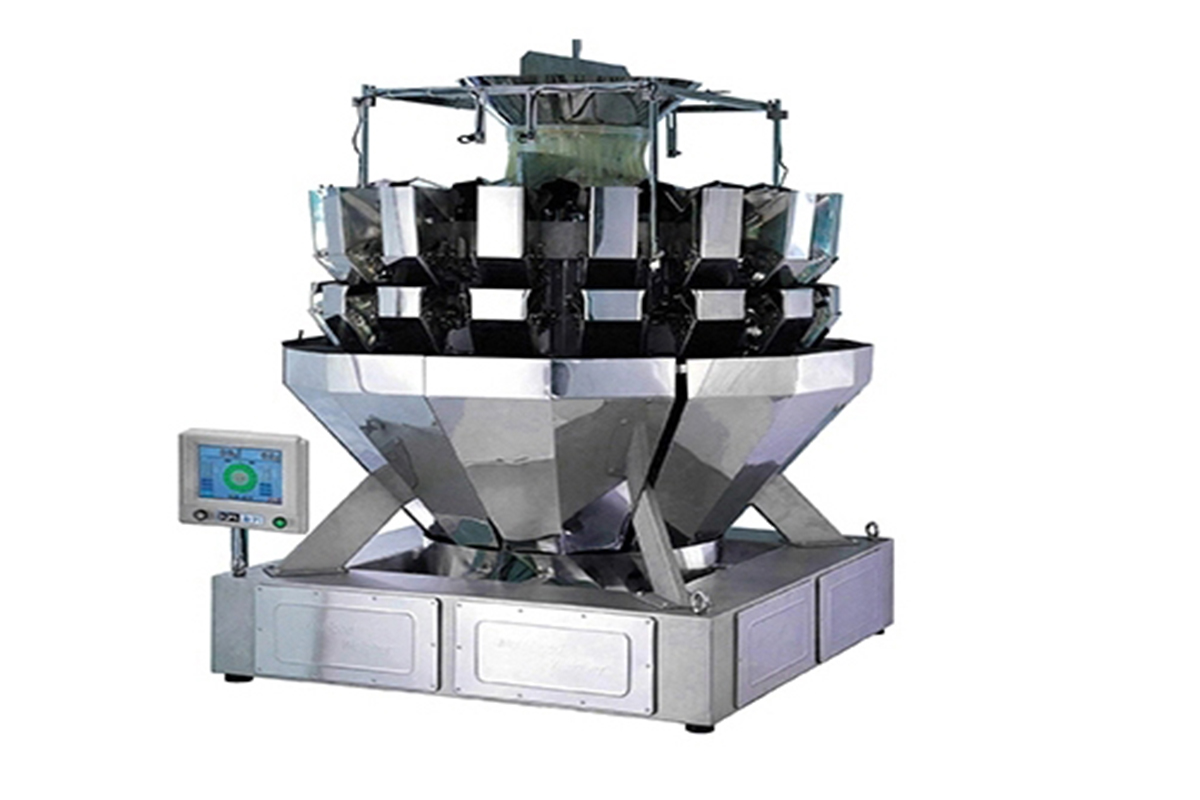

The core of a multihead weigher is its combination algorithm. Here’s how it works:

Feeding: The product is distributed to multiple weigh heads via vibration feeders.

Individual Weighing: Each weigh head independently measures a small portion of the product.

Combination Calculation: The central control system calculates the best combination of weights across the heads that is closest to the target weight (e.g., 100g).

Discharge: Selected weigh heads release their contents simultaneously into the downstream packaging system.

This dynamic combination process allows high-speed and highly accurate weighing with minimal product loss.

Central Processing Unit (CPU): Controls the weighing process and performs combination calculations.

Weighing Heads: Equipped with load cells for precise weight detection.

Vibration Feeders: Distribute product evenly into each head.

Hoppers & Discharge Mechanism: Control the release of product to the packaging system.

HMI (Human-Machine Interface): Used for setting target weights, speed, and other parameters.

High Speed: Can achieve up to 120 weighings per minute, far faster than traditional linear weighers.

High Accuracy: Typical weight deviation is within ±0.1–0.5 grams.

Intelligent Algorithms: Ensures minimum giveaway by selecting the optimal weight combination.

Versatility: Suitable for a wide range of product types and sizes.

Integration Ready: Easily connects with vertical form-fill-seal machines or premade pouch packaging machines.

| Industry | Typical Products |

|---|

| Food | Snacks, nuts, frozen foods, candies |

| Pharmaceuticals | Pills, granules |

| Hardware | Screws, bolts, washers |

| Daily Chemicals | Detergent pods, tablets |

| Agriculture | Seeds, grains, beans |

When selecting a multihead weigher, consider the following factors:

Product Flow Characteristics: Free-flowing products are best suited.

Target Speed (bags/minute): Choose head count based on your production capacity.

Accuracy Requirements: High-value products may require tighter tolerances.

Environmental Conditions: Consider waterproofing, anti-corrosion, or dustproof features.

Packaging Integration: Ensure compatibility with your existing packaging machinery.

The multihead weigher has revolutionized automatic weighing in packaging systems by offering unmatched speed and accuracy. Whether you’re packaging food, hardware, or chemicals, investing in the right multihead weighing solution can drastically improve productivity and reduce material waste.

Need expert advice on selecting the right multihead weigher for your product line? Contact us for tailored solutions and technical support.

No. 1111, Rong da Road, Shang wang Street, Rui an City, Wen zhou City, Zhejiang Province.

If You Would Like To Visit Our Just Now,Please Contact Us and We Will Arrange a Special Bus To Pick You Up.

Copyright © 2025 Ruian Joye Machinery CO.,LTD All Right Reserved

No. 1111, Rong da Road, Shang wang Street, Rui an City, Wen zhou City, Zhejiang Province.

If You Would Like To Visit Our Just Now,Please Contact Us and We Will Arrange a Special Bus To Pick You Up.