WordPress Dev.

It is suitable for various packaging containers

We have listed some questions you may ask. If you have more inquiries about our filling machine, you can send an inquiry to contact us.

Our machines are suitable for purified water, mineral water, spring water, and even sparkling water with proper configuration. We also support hot-filling if required.

Yes. Our machines support multiple bottle sizes and shapes, with quick-changeover features that allow for easy switching between formats.

We offer machines with output capacities from 1,000 to 24,000 bottles per hour (BPH), depending on your production scale and bottle size.

Absolutely. We provide dedicated 5-gallon (18.9L) water filling systems, complete with barrel washing, filling, and capping units.

Yes. All our water filling lines come with automatic capping systems, compatible with various cap types, including screw caps and press caps.

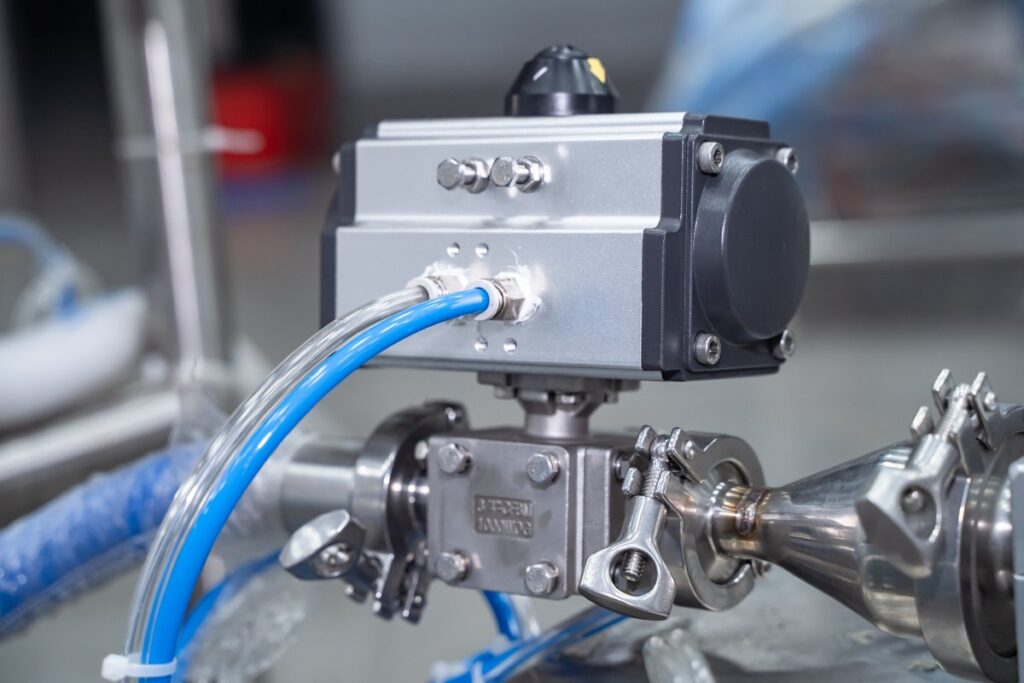

Yes. Our machines use 304/316L stainless steel, food-grade components, and can be equipped with CIP cleaning systems, UV sterilizers, and HEPA filtration to meet international hygiene standards (e.g., CE, GMP, FDA).

e

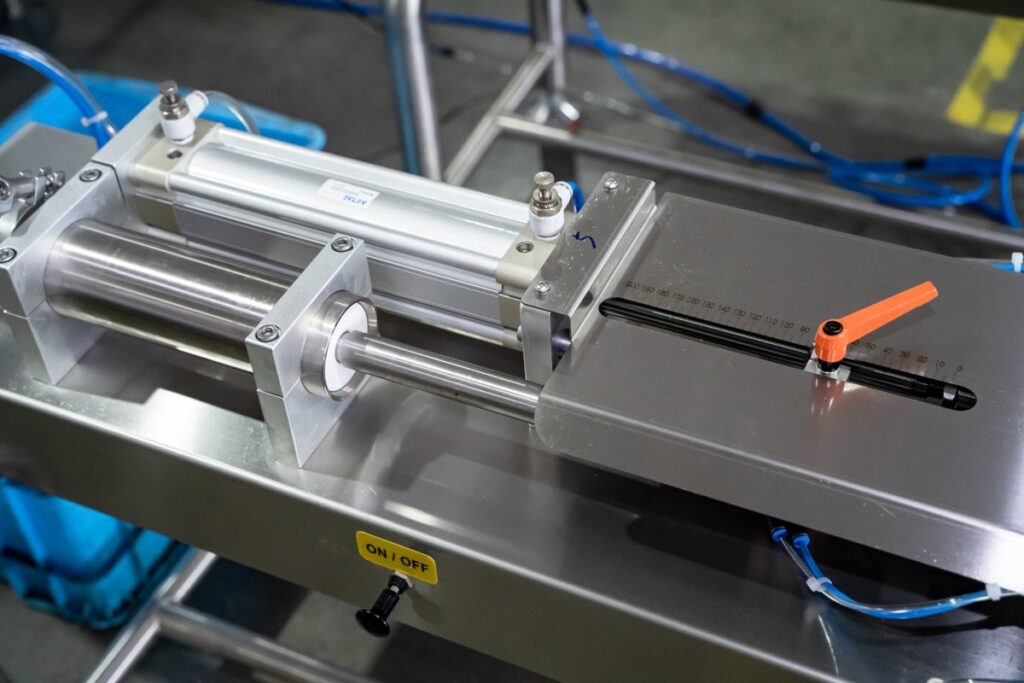

Typically, our systems require power supply, compressed air, water inlet, and drainage. We will provide a utility layout and installation guidance with your order.

Yes. We offer remote and on-site technical support, operator training, and lifetime maintenance service. Spare parts are available long-term.

We provide our clients with top-quality machines and good maintenance services as well.

We welcome customers to visit our factory, whether it is to check our machines, to consult the feeding filling plan, or to understand the operation of the equipment.

No. 1111, Rong da Road, Shang wang Street, Rui an City, Wen zhou City, Zhejiang Province.

If You Would Like To Visit Our Just Now,Please Contact Us and We Will Arrange a Special Bus To Pick You Up.

Copyright © 2025 Ruian Joye Machinery CO.,LTD All Right Reserved

No. 1111, Rong da Road, Shang wang Street, Rui an City, Wen zhou City, Zhejiang Province.

If You Would Like To Visit Our Just Now,Please Contact Us and We Will Arrange a Special Bus To Pick You Up.